APPLICATION

Our Nozzles are used in wide range of application includes food processing industries, Chemical spraying, coating, lubrication, dust suppression..etc

Industrial SPRAY Nozzles

We manufacture wide range of Industrial and Agricultural Spray Nozzles designed with various materials and flow patterns to satisfy industy needs

INDUSTRIES

Our nozzles are used in food processing, chemical processing, pollution control, water treatment, paper and many other industries

SPRAY NOZZLE MANUFACTURER

SYNERGY SPRAY SYSTEMS will advise and manufacture perfect spray nozzles for your requirements.

SPRAY NOZZLE

A spray nozzle is a simple device used to break apart a fluid flow into a spray pattern. Despite the apparent simplicity of nozzles there are a very large number of different products in our range reflecting the multitude of ways different industries need to spray various fluids.

Flat fan nozzles

Flat fan nozzles produce a line of spray. They are often used in coating and cleaning applications on conveyors where product is passed under a spray bar of several fan nozzles. There are two main designs of fan nozzle: deflection and a standard shaped orifice.

Full cone nozzles

Full cone nozzles produce a solid circle of spray. These nozzles are used when the objective is to distribute the fluid evenly over an area. As with the hollow cone nozzles there are three designs of nozzle that can produce full cone patterns.

Misting nozzles

Mist or fog patterns are characterised as having the fluid finely atomised with little or no momentum. A homogeneous fog is produced that is largely directed by surrounding air flows rather than by the nozzle itself. There are two design types that produce this pattern: impingement and small orifice.

Solid stream nozzles

The straight jet pattern concentrates the fluid into a high impact dot of spray. The aim of such nozzles is generally to deliver as much impact as possible for cleaning or cutting applications. Other low impact uses can include for the precision delivery of fluid to specific parts of a process. There are two design types for this pattern: a standard shaped orifice nozzle and enhanced laminar flow design.

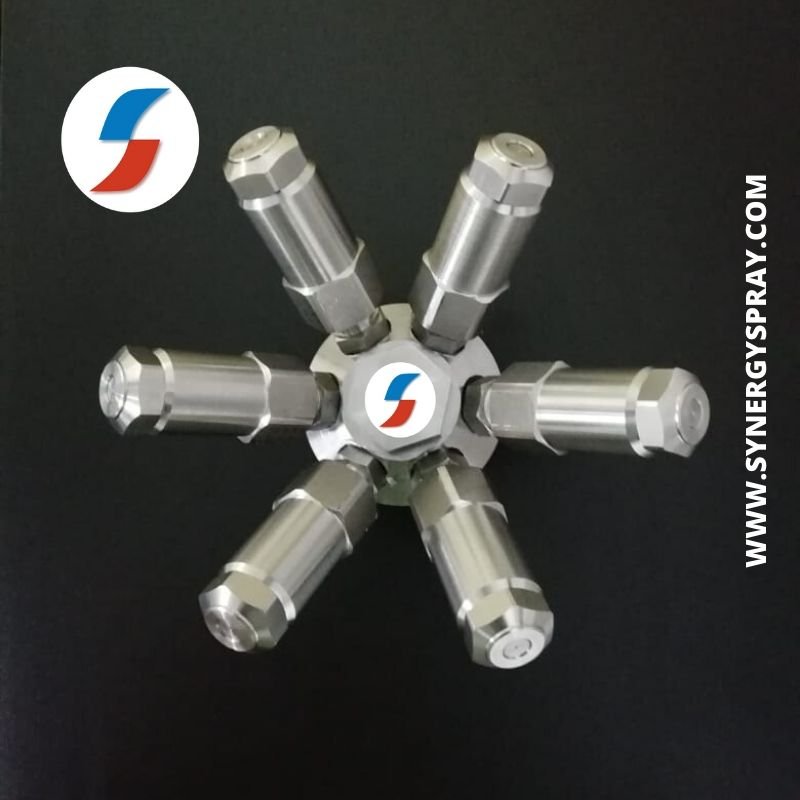

Tank cleaning

The tank cleaning “pattern” requires fluid to be delivered to the whole area of a vessel that needs cleaning. Typically this means a 360o delivery of fluid. There are 3 basic designs of tank cleaner that will achieve this: rotary jet cleaners for high impact, rotary fan cleaners for medium impact and cleaners for low impact.

Find Us

Contact us

+91 86100 00128

+91 94442 75778

+91 94999 72778